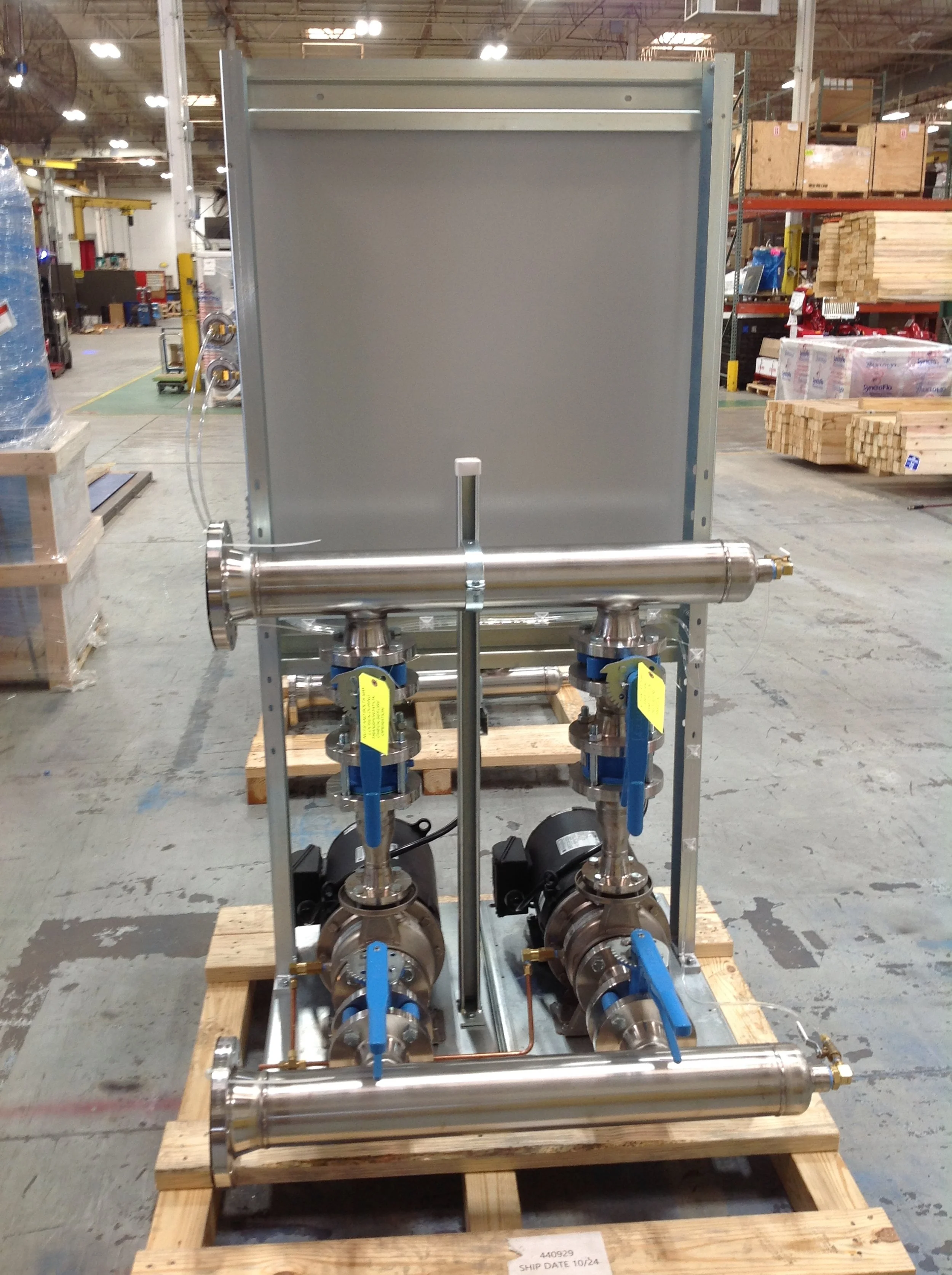

Features include 100% flanged construction, High performance check valves for low station losses, 304 Stainless steel pumps, Bolt on panel stand, NEMA 12 enclosure with air filter and fan for heat dissipation.

Horizontally Mounted CCES Pumps

Vertically Mounted CCES Pumps

Vertical Multistage

Factory testing is the best method to be certain of performance capability in the field. In many instances, factory testing is the only systematic way to test the pumping package at design point. It also saves time during installation, since the pumping system arrives at the jobsite with all adjustments preset to the specified conditions.

Trained instrument technicians conduct a battery of hydraulic and electrical tests designed to reliably assure predictable pumping system performance. Jobsite conditions are precisely duplicated and each system is conveniently "field tested" in our factory before it is shipped. The many adjustments and startup problems associated with field-built pumping system installations are effectively eliminated. All SyncroFlo system tests may be witnessed by the owner, engineer, or contractor. The system test will begin approximately one week before the scheduled shipment date. Witness can be in-person, or via webcam.

We’re proud our systems reach 20+ years of life! However, we strongly recommend a retrofit for quicker service, energy savings and availability of replacement parts. Worried about the cost of piping? Ask our team about plug-and-play installation.

Just take a look at a Before & After below.

If you need help selecting a system, please contact your local SyncroFlo Rep! Have the specifications ready for a quote. Unrepresented areas can contact Our Team.

Supporting Our Heroes

SyncroFlo, Inc. is a proud sponsor of the Heroes First Foundation whose commitment supports military and first responder families. Since 2012, they have contributed funds for paws4vets. If you’d like to participate in the annual charity golf outing please register in advance.